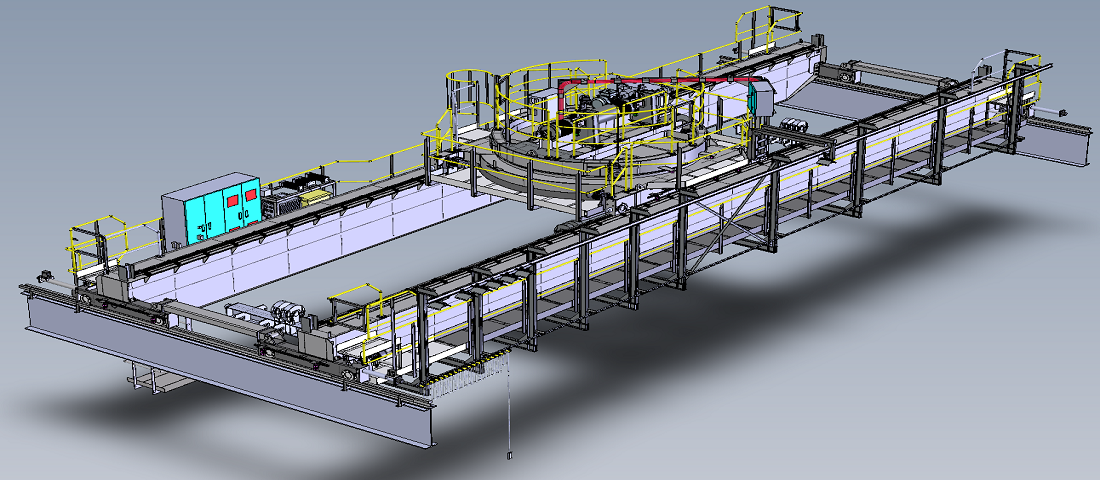

Process Cranes

Process cranes are crane systems that go beyond standard load handling, forming an essential part of specific production processes, requiring special design and high-level engineering.

They play a critical role in heavy industrial plants, ensuring the continuity and safety of production.

Our Company’s Approach to Process Cranes

Our company manufactures process cranes in accordance with international quality standards (ISO, CE, etc.). In each project, we deeply analyze sectoral needs and operational expectations, developing the most accurate solutions through our engineering expertise. Our extensive engineering experience, combined with knowledge gained from field operations, enables us to offer our customers both safe and long-lasting crane systems. Our products are designed to deliver maximum efficiency even under harsh operating conditions; we never compromise on quality, safety, and durability principles.

The Importance of Process Cranes

Process cranes ensure production processes proceed without interruption, quickly and safely.

These cranes are not just load-handling tools but strategic equipment that directly affect the efficiency of production lines.

An incorrectly selected or low-quality process crane can lead to production loss and pose serious occupational safety risks.

Therefore, the importance of process cranes designed with proper engineering solutions is increasing every day.

Examples of Process Cranes:

1. Foundry Cranes

Special cranes for transporting molten metal at high temperatures.

Used in iron-steel plants.

Equipped with heat-resistant hooks and bridge structures.

2. Slab and Billet Handling Cranes

Used in steel factories for handling slabs, blooms, and billets.

Have heavy load-bearing capacities.

Can be equipped with magnetic or clamp-type grabbers.

3. Rolling Mill Cranes

Used for transporting steel sheets within rolling mills.

High-speed movement and durability are prioritized.

4. Paper Roll Handling Cranes

Specifically designed for the precise handling of large rolls in the paper and pulp industry.

Uses special apparatus that grip rolls without damaging them.

5. Power Plant Cranes (Turbine Cranes)

Used for assembling and transporting turbines and generators in hydroelectric, thermal, and nuclear plants.

Must have extremely precise positioning capabilities.

6. Electrolysis Cell Cranes

Used in electrolysis plants producing aluminum and other metals.

Made from materials resistant to aggressive chemical environments.

7. Cement Plant Cranes

Used for handling heavy materials in raw material stockyards or production lines of cement factories.

Designed for dusty and abrasive environments.

8. Petrochemical Facility Cranes

Used in the installation and maintenance of tanks, reactors, and heavy equipment.

Manufactured to ATEX standards for operation in explosive-risk zones.

9. Nuclear Power Plant Cranes

Specially designed cranes with radiation protection.

Use high-security protocols and redundant systems.

10. Automotive Industry Process Cranes

Designed for precise transport tasks like chassis assembly and die changes.

Must operate fast and precisely.

Our company combines quality and engineering strength to target maximum efficiency and durability in process crane systems.

Load Capacity: Customizable from 5 tons to 500 tons.

Working Environment: Special design options for high temperature, dusty, chemically active, or abrasive environments.

Precision: Positioning precision at the millimeter level.

Control Systems: Automatic drive systems, remote control, and full automation options.

Energy Efficiency: Low energy consumption with modern motor systems and smart drives.

Safety Equipment: Collision prevention systems, overload protection, speed limiters, and emergency stop systems are standard.

Maintenance Recommendations

Regular maintenance is vital for the efficient and long-lasting operation of process cranes.

Our basic maintenance recommendations as a company are:

Periodic Checks: Annual or more frequent maintenance depending on usage intensity.

Lubrication: Regular lubrication of moving parts reduces friction and wear.

Electrical System Checks: Cable connections, contactors, and limit switches should be tested regularly.

Testing Safety Equipment: Ensure load sensors and emergency stop systems function correctly.

Operator Training: Crane operators should be trained on proper usage and emergency procedures.

During maintenance, the use of original spare parts and authorized service significantly extends product life.

Our company is not just a crane manufacturer but also a solution partner that enhances the productivity of its business partners.

With after-sales technical support, spare part supply, and maintenance services, we continue to stand by our customers at all times.

If you want to make your lifting systems more efficient, safer, and more flexible, contact us.

Let’s take your production one step further with our custom process crane solutions!

Industry Developments and the Future

Today, process crane technologies are rapidly evolving with Industry 4.0 compatible solutions.

Our company develops crane systems compatible with the factories of the future by offering customers innovative solutions such as remote monitoring, data analysis, and automation.

Smart Crane Systems: Fault prediction algorithms and remote maintenance support

Energy Monitoring: Real-time energy consumption analysis for cost optimization

Environmentally Friendly Production: Energy-efficient motors and production techniques that comply with environmental standards

By closely following evolving technology, we offer our customers solutions in process crane projects that meet not only today’s but also future needs.