Structural Analysis and Reporting in Gantry Cranes

Gantry cranes are critical lifting systems that enable the safe, precise, and fast transportation of heavy loads. When integrated with industrial automation and control technologies, these cranes increase production efficiency, reduce operational costs, and significantly enhance workplace safety.

Structural Analysis and Reporting in Gantry Cranes

Gantry cranes are critical machines for heavy load handling and lifting in industrial areas. Their safety, efficiency, and longevity are directly related to accurate structural analyses and detailed reporting. Structural analysis is used to determine how cranes behave under various loads, identify potential weak points, and suggest design improvements. These analyses also play a vital role in establishing safety measures and maintenance plans.

Importance of Structural Analysis

The structural analysis of gantry cranes enables engineers to accurately determine the load-bearing capacity and durability of each component. This analysis is a crucial step to ensure the structural safety of the cranes, improve operational efficiency, and reduce the risk of failures. Structural analysis examines the effects of static and dynamic loads on cranes during operation.

The goals of these analyses are to:

Increase safety levels,

Optimize load-bearing capacities,

Predict future maintenance and repair needs,

Improve energy efficiency.

Structural Analysis Methods:

A variety of engineering methods and simulation tools are used in the structural analysis of gantry cranes. These methods accurately assess the load capacity, durability, and performance of the cranes.

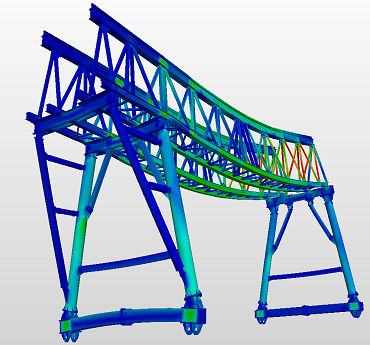

Finite Element Method (FEM):

This method models each part and joint of the crane as small elements, simulating how they behave under various load conditions. FEM is commonly used to perform structural stress, deformation, and vibration analyses.

Static and Dynamic Loading Analyses:

In addition to static loads, dynamic loads that occur during operation are also analyzed. The effects of these loads are calculated according to the design and durability of the crane.

Fatigue and Stress Analyses:

Fatigue and stress conditions that may occur in cranes due to long-term use are examined. These analyses help identify potential weak points and eliminate safety risks.

Reporting and Improvement Suggestions

The data obtained from structural analyses are presented in detailed reports. These reports reveal the current condition of the cranes and highlight any structural issues. Furthermore, the reporting process provides suggestions for design improvements and modifications. Structural analysis reports include the following information to ensure the safe operation of the cranes:

Load Capacity Assessment: The crane’s suitability for its maximum load capacity and potential load limits.

Structural Reinforcement Needs: Identifying weak areas and proposing strengthening measures.

Fatigue Test Results: Reporting potential fatigue points from long-term use.

Maintenance and Repair Needs: Maintenance and repair plans to enhance structural durability.

Conclusion

Structural analysis and reporting in gantry cranes form the foundation for creating a safe and efficient working environment. Proper and effective structural analyses ensure that cranes can operate safely for a long period. Moreover, these analyses contribute to making cranes more efficient during the design and usage stages, helping reduce maintenance and repair costs. High-quality structural analysis and reporting increase productivity in industrial facilities while maximizing workplace safety.

Contact Us