Gantry Crane Travelling Mechanism: Powerful, Precise, and Safe Movement System

Gantry cranes are critical lifting systems that allow the precise, safe, and fast transportation of heavy loads. When integrated with industrial automation and control technologies, these cranes enhance production efficiency, reduce operational costs, and maximize workplace safety.

What is the Travelling Mechanism in Gantry Cranes?

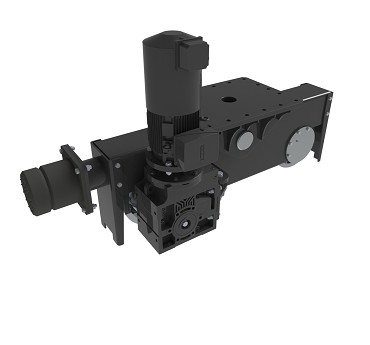

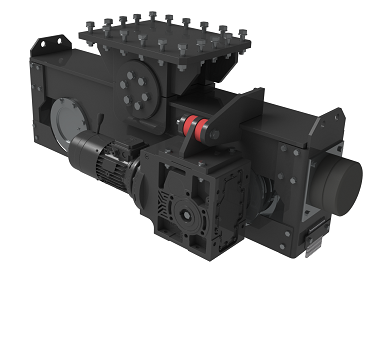

The gantry crane travelling group is composed of mechanical and electrical components that enable smooth and controlled movement on rails. It is one of the most critical systems ensuring efficient operation in production plants, ports, warehouses, and open areas.

Balance and Stability:

The crane trolley moves symmetrically on double girders. This structure balances the load distribution, extends system lifespan, and reduces operational risks.

Technical Features of Gantry Crane Travelling Mechanism

Drive Motors and Gear Units:

The electric motors at the core of the system are typically equipped with frequency inverters and load control for smooth starting and precise stopping. Gear units increase torque, allowing stable movement under heavy loads.

Wheel and Bearing Systems:

Wheels made from steel or cast material ensure optimal contact with rails and reduce friction. Bearing systems balance lateral loads and extend the lifespan of the travelling system. Dual-driven wheel systems help balance asymmetric load distribution.

Braking and Safety Mechanisms:

Electromagnetic brakes ensure safe stops during emergencies. Travel limit sensors and bumpers prevent system damage at the end of rails. The synchronization system ensures coordinated linear motion in double girder cranes.

Design and Mechanical Performance of Gantry Crane Travelling System

Modular Design for Easy Maintenance:

Gantry crane travelling systems are usually modular in structure. This allows quick part replacement during failures and easy integration into cranes of different capacities.

Heavy-Duty Material Usage:

Protective coatings and weather-resistant paint guard the system against rust and wear. All components are manufactured from high-strength steel.

Vibration and Noise Dampening Structure:

Mechanical vibration and noise during movement are reduced using special shock-absorbing rubber buffers.

Sales and Marketing Perspective of Gantry Crane Travelling Mechanism

Why Choose a High-Quality Travelling Mechanism?

Operational Continuity:

Poor-quality systems cause breakdowns and downtime in production, resulting in time and labor loss. A robust travelling mechanism enables uninterrupted operations.

Long Lifespan and Low Maintenance Cost:

A well-designed system operates for extended periods without requiring maintenance, reducing total cost of ownership (TCO).

Sectoral Compatibility and Project Customization:

Each project involves different ground, load, and operational conditions. When offered with customized engineering support, the travelling mechanism maximizes customer satisfaction.

Contact Us