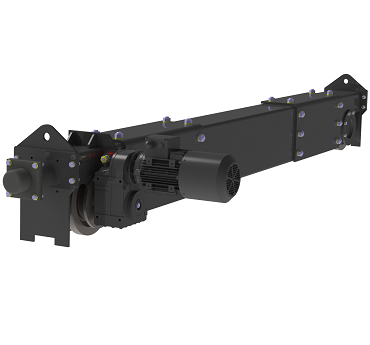

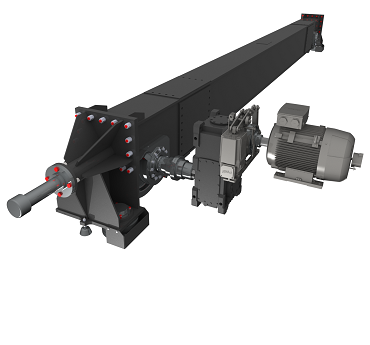

Overhead Crane Endcarriages: The Perfect Mechanism for Dynamic Movement

In industrial lifting systems, the structure that ensures the safe, balanced, and synchronized movement of the traveling crane bridge is the "Overhead Crane Endcarriages". This group is the power center that moves and positions the crane bridge linearly on building or outdoor rails. A poorly designed drive group negatively affects the efficiency and safety of the entire system. Therefore, criteria such as high performance, precision, and durability must be prioritized in the production of the Overhead Crane Endcarriages.

Components and Function of the Overhead Crane Endcarriages

🔧Drive Motors

Usually, frequency-controlled and inverter-supported AC motors are preferred. Thanks to these motors, crane movement occurs smoothly, precisely, and quietly. Energy consumption is optimized; the motor uses only the required power.

⚙️Gearbox and Torque Transmission

Planetary or helical gearboxes used in the drive system strengthen torque transmission. Smooth drive is ensured even under load.

⚙️Wheel Group and Rail Compatibility

High-strength steel or cast iron wheels are used. They are designed with special diameter and hardness suitable for rail width and load capacity. Idle balance wheels tolerate deviations on the rail.

🧠Synchronization and Smart Control

In dual-motor systems, automatic sync control algorithms eliminate risks like bridge skew and wheel jamming. In PLC-supported systems, faults are detected in advance minimizing downtime.

🛡️Safety and Durability Criteria

Electromagnetic brakes safely hold the load in case of power failure.

Limit switches prevent the bridge from hitting the end of the rail.

Buffer systems protect the bridge structure against mechanical impacts.

All these systems are integrated in compliance with machine safety standards like ISO 13849-1.

Role of R&D and Innovation in Overhead Crane Endcarriages

Nowadays, modern cranes are not only for lifting but also data analysis and automation-focused systems.

New technologies developed in the bridge drive group include:

IoT-based drive monitoring systems

AI-supported braking optimization

Software performing vibration analysis and fault prediction

Contact Us